Understanding What Makes Fire Blankets Work

Fire blankets are essential for quickly extinguishing small fires. Their effectiveness depends heavily on the materials used in their construction. These materials need to form a barrier between the fuel and oxygen, effectively smothering the flames. The material also needs to withstand high temperatures without breaking down or transferring too much heat to the user.

This balance of functionality and safety is critical for a fire blanket to do its job reliably.

Key Material Properties for Effective Fire Suppression

Several key properties determine a fire blanket’s effectiveness:

-

Heat Resistance: The material must withstand high temperatures without melting, burning, or losing its structural integrity. This prevents the blanket from becoming part of the fire and ensures it continues to provide a protective barrier.

-

Low Thermal Conductivity: This property minimizes heat transfer through the blanket, protecting the user from burns and stopping the fire from spreading.

-

Flexibility and Drapability: A fire blanket needs to be flexible enough to conform to the shape of the burning object and drape over it effectively. This creates a complete seal, cutting off the oxygen supply.

-

Durability: The material should be resistant to tearing, abrasion, and other damage, ensuring it remains usable in emergencies.

Common Fire Blanket Materials and Their Performance

Fire blankets are usually made from highly heat-resistant and durable materials. Silica, capable of withstanding temperatures up to 1,800 °C, is a common choice. Fiberglass, often treated with silicone coatings for enhanced safety and thermal resistance, is another popular material. Learn more about fire blanket materials from Vlitex. These materials are chosen for their ability to effectively smother flames and protect the user.

How Material Choice Impacts Fire Blanket Performance

The material used significantly affects a fire blanket’s performance in different situations. For instance, a fiberglass blanket might be suitable for a small kitchen fire, but less effective against a high-intensity industrial fire. This is because temperature thresholds and durability vary depending on the material composition and construction. Therefore, understanding a fire blanket's material composition is crucial for selecting the right one for your needs.

Why Material Selection Matters for Safety

Choosing the right fire blanket material is vital for safety. Some materials, like untreated fiberglass, release irritating fibers at high temperatures, creating a health hazard. Opting for a fire blanket with a silicone coating can greatly improve safety during use and provide extra heat resistance. Understanding the materials and their properties helps you make informed decisions, selecting a fire blanket that offers the best protection in an emergency.

Fires don't warn you.. but we do.

Peace of mind starts with the right protection.

Explore the Best Fire BlanketsFiberglass Fire Blankets: Why They Dominate The Market

Fiberglass has become the most common material for fire blankets. Its widespread use isn't accidental. This article explores why fiberglass is the top choice for both manufacturers and consumers. We'll trace its journey from raw material to essential safety equipment.

The Appeal of Fiberglass in Fire Blankets

Fiberglass offers a powerful combination of affordability and effectiveness. Its natural heat resistance allows it to withstand extreme temperatures, effectively smothering flames by cutting off their oxygen supply.

Fiberglass is also relatively easy to manufacture and widely available. This makes it a cost-effective choice for mass production, ensuring that fiberglass fire blankets are accessible to a wide consumer base.

Consider a small grease fire on a kitchen stove. A fiberglass fire blanket can quickly extinguish the flames, preventing a minor incident from becoming a major disaster. This ease of use and accessibility are key factors in its popularity.

Addressing the Drawbacks of Fiberglass

While fiberglass has many advantages, it’s important to acknowledge its limitations. One drawback is the release of irritating fibers when exposed to high temperatures. These fibers can be a health hazard, especially if inhaled. That's why protective gear is recommended when using fiberglass fire blankets, particularly in larger fires.

This issue can be mitigated with a silicone coating, which can be found in all fireblanket.com's products. This coating not only reduces fiber irritation, but also improves the blanket's heat resistance and durability. This makes silicone-coated fiberglass blankets a safer and more efficient option for various uses. Learn more about the different types of fire blankets and their best uses here.

Silicone Coatings: Enhancing Safety and Performance

Silicone coatings address the main concerns associated with standard fiberglass fire blankets. The coating acts as a barrier, preventing the release of irritating fibers and boosting overall heat resistance. This added protection is especially important for home use where fiber exposure is a greater concern.

Silicone-coated fiberglass blankets offer a blend of affordability, effectiveness, and enhanced safety. They are a versatile solution suitable for many applications, from home kitchens to industrial settings. You can find more information on fiberglass fire blankets in this guide.

To better understand the differences between various fire blanket types, let’s examine a comparison of their specifications. The table below highlights the key features and benefits of each.

Fiberglass Fire Blanket Specifications Comparison

| Material Type | Max Temperature | Coating | Best Use Case | Safety Rating |

|---|---|---|---|---|

| Woven Fiberglass | 550°C (1022°F) | None | Industrial settings, welding | Moderate |

| Woven Fiberglass | 550°C (1022°F) | Silicone | Home kitchens, garages, cars | High |

| High-Silica Fiberglass Cloth | 1093°C (2000°F) | Vermiculite | Welding, foundry work, industrial ovens | Very High |

As the table illustrates, different types of fiberglass fire blankets cater to specific needs and safety requirements. While basic woven fiberglass blankets are suitable for industrial use, silicone-coated options are better for home environments. High-silica cloth with vermiculite coatings provide the highest level of protection for extreme temperature applications. Choosing the right blanket depends on the intended use and desired safety level.

Silica-Based Fire Blankets: Premium Performance Explained

While fiberglass fire blankets are common, some circumstances require a higher level of protection. That's where silica-based fire blankets come in. These blankets offer enhanced performance, making them ideal for high-risk areas. Let’s explore what sets silica apart and why it’s a worthwhile investment.

Understanding the Power of Silica

Silica, also known as silicon dioxide, has exceptional heat resistance. This inherent quality makes it perfect for fire blankets designed to endure extreme temperatures. Silica’s molecular structure allows it to stay stable even when exposed to intense heat, surpassing the performance of many other materials.

For instance, silica can handle temperatures far beyond the limits of standard fiberglass. This makes silica-based fire blankets suitable for industrial settings, commercial kitchens, and other high-risk locations where extreme heat is a constant concern.

Manufacturing Process: From Raw Material to High-Performance Blanket

The creation of silica fire blankets involves converting raw silica into a woven fabric. This requires specialized weaving techniques to achieve a strong and flexible material. The fabric also frequently undergoes treatments to boost its fire-resistant properties. You might find this interesting: How silicone adds an extra layer of protection to fire blankets.

This careful process results in a fire blanket that’s not only incredibly durable but also highly effective at putting out flames. The tight weave blocks oxygen, effectively smothering the fire. This allows silica-based blankets to quickly extinguish fires, minimizing damage and potential injuries.

When to Choose a Silica Fire Blanket

Silica fire blankets offer substantial benefits in specific circumstances, justifying their higher price. In industrial environments dealing with molten metals or extremely high temperatures, silica offers unmatched protection. Likewise, in commercial kitchens where grease fires are a regular hazard, the superior heat resistance of silica provides an additional safety measure.

Silica blankets are also commonly used in laboratories and other specialized locations handling volatile chemicals or high-temperature equipment. In these situations, the added cost is balanced by the increased safety and reliability of silica. This makes them a crucial investment for protecting both people and property.

Silica's Superiority in Extreme Conditions

In short, silica-based fire blankets are the best option for extreme temperatures and high-risk fire hazards. Their strong construction, exceptional heat resistance, and ability to effectively smother flames make them essential for challenging applications. While fiberglass remains suitable for many common fire scenarios, silica offers a significant improvement in protection where top-tier performance is critical.

Safety is a priority

Our fire blankets meet the highest safety standards.

Shop Fire Safety ProductsAdvanced Materials and Coating Technologies

Moving beyond familiar fiberglass and silica, fire blanket materials are constantly evolving. This article explores the advanced materials and coatings that are pushing the boundaries of fire safety. We'll delve into how these innovations improve fire blanket performance in challenging situations.

Exploring Cutting-Edge Materials

Ceramic fibers, known for exceptional heat resistance and low thermal conductivity, are becoming increasingly popular for high-temperature applications. These fibers withstand temperatures far exceeding those tolerated by standard fiberglass, making them suitable for industrial furnaces and other extreme environments. Carbon composites, another developing material, offer remarkable strength and heat resistance. Their lightweight nature makes them ideal for specialized applications where maneuverability is key, such as in the aerospace or motorsport industries.

Additionally, specialized synthetic materials like Nomex and Kevlar are increasingly used for fire blankets where chemical resistance and durability are essential. These materials provide excellent protection against specific hazards, expanding the use of fire blankets beyond basic fire suppression.

The Role of Advanced Coatings

Modern coating technologies play a vital role in enhancing fire blanket performance and safety. Silicone coatings, for example, improve the heat resistance and flexibility of fiberglass blankets while minimizing fiber irritation. PTFE (polytetrafluoroethylene), known for its non-stick properties and high melting point, provides another layer of protection in applications involving grease or chemical fires. Furthermore, proprietary compounds are constantly being developed to improve qualities like water repellency, abrasion resistance, and overall longevity.

These advancements not only increase the lifespan of fire blankets but also expand their use in various hazardous environments.

Emerging Applications and Performance vs. Cost

The development of advanced materials and coatings creates new opportunities for fire blankets in specialized industries. In aerospace, lightweight carbon composite blankets protect sensitive equipment during launch and flight. In marine environments, water-repellent and corrosion-resistant coatings ensure reliable performance in harsh conditions. Similarly, specialized industrial settings, like chemical processing plants, benefit from blankets made with chemically resistant synthetic materials.

However, these advanced materials often come with a higher cost. It's important to balance performance and budget. While advanced materials are beneficial in specific high-risk situations, standard fiberglass or silica blankets may suffice for common household or small business needs. Understanding these differences is vital for making informed purchasing decisions, avoiding unnecessary expenses while ensuring adequate safety. Selecting the right fire blanket involves carefully considering the specific hazards, required performance, and budget.

Fire Blanket Market Growth And Material Innovation

The fire safety industry is constantly changing, driven by new materials and evolving safety rules. This creates a dynamic environment that fosters innovation and shapes market trends. These trends affect everything from how fire blankets are made to how they are used. Let's explore the key forces influencing this market and how they are changing the industry.

Market Trends and Material Development

The fire blanket market is growing significantly. This growth is driven by increased awareness of fire safety and more stringent regulations. The demand for lighter, more durable, and eco-friendly materials is pushing manufacturers to explore new options.

Traditional materials like fiberglass and silica are being challenged by newer alternatives. These include ceramic fibers and intumescent coatings, each offering unique properties for specific uses. We're also seeing more specialized fire blankets designed for specific applications. These include kitchens, industrial settings, and even electric vehicles.

The global fire blanket market was valued at $296.03 million in 2023. It's projected to reach $407.92 million by 2030, with a CAGR of 5.48% from 2024 to 2030. You can find more detailed statistics here. This impressive growth underscores the increasing importance of fire blankets across various sectors.

Regulatory Landscape and Regional Preferences

Government regulations heavily influence the materials used in fire blankets. Different regions have unique standards and certifications. Some areas might require specific flame-retardant treatments. Others might prioritize environmentally friendly materials.

These regional differences present challenges for manufacturers. However, they also encourage innovation and ensure better safety for consumers. Understanding local regulations is critical for selecting a compliant and effective fire blanket.

Investment Trends and Emerging Opportunities

Market growth has attracted significant investment in research and development. This has led to advancements in manufacturing and the exploration of new materials. For example, nanotechnology is being employed to create fire blankets with improved heat resistance and durability.

There's also increasing interest in "smart" fire blankets. These incorporate sensors and alarms for early warnings and faster response times. Such advancements are transforming fire safety. As the market evolves, we can anticipate further innovations, leading to even more effective and specialized fire blankets. Fire blankets are no longer just basic safety tools; they're becoming sophisticated pieces of technology designed to save lives and protect property.

Every second counts

Quick access to fire protection could save lives.

Get Protected TodayChoosing The Right Fire Blanket Material For Your Situation

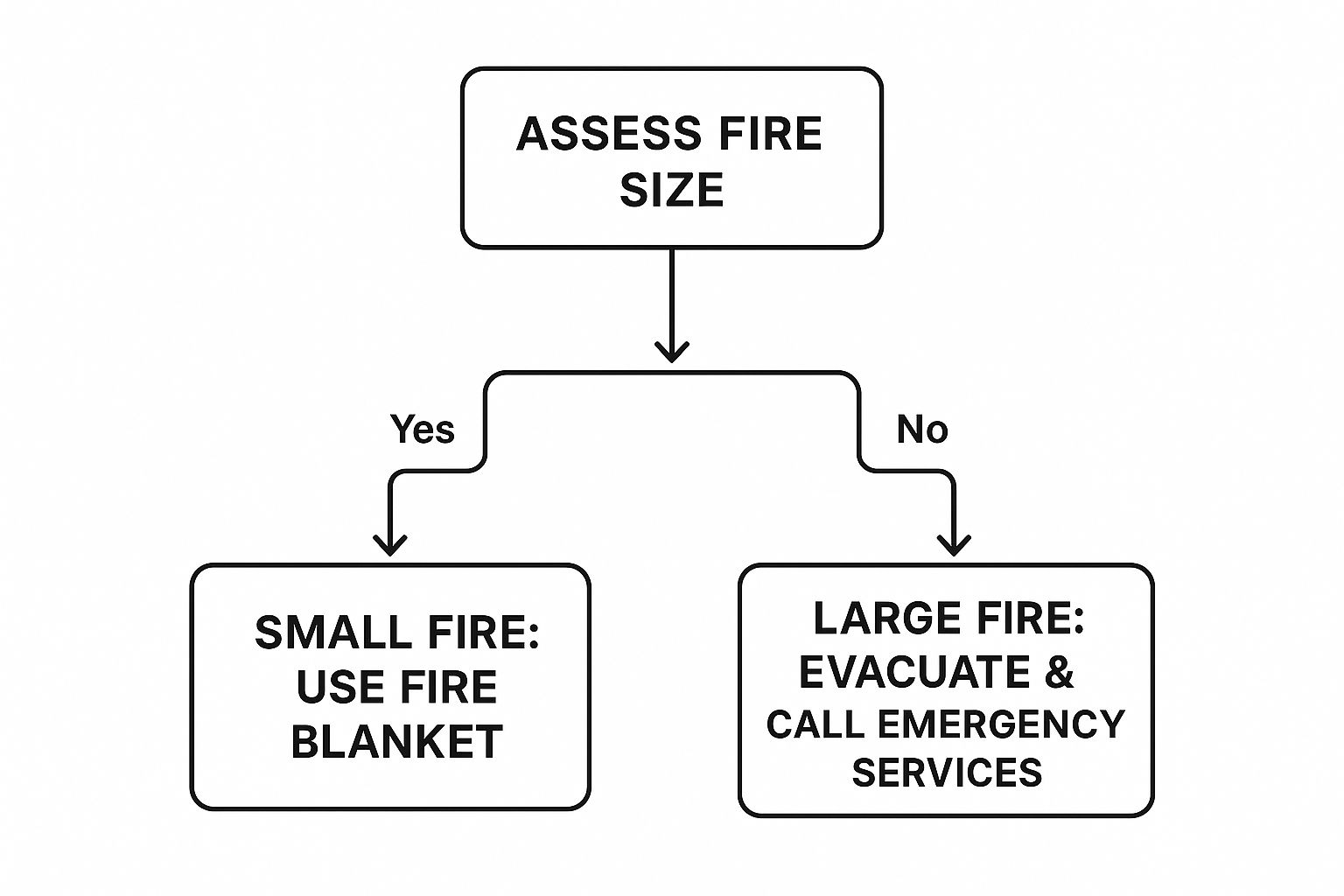

This infographic gives you a simple way to decide how to react to a fire. First, figure out how big the fire is. If it's small, a fire blanket can help. If it's large, get out and call for help. The main point? Fire blankets are for small fires, not big ones. For bigger fires, your safety comes first. Get out and call the fire department.

Choosing the right fire blanket depends on how and where you’ll use it. A blanket for your home kitchen might not work in a factory. Knowing the pros and cons of each material helps you choose the right one. Let's look at how things like your budget and how easy the blanket is to maintain affect your decision. Also, check out this article: Fire Blanket vs. Fire Extinguisher - Which Is Safer For You?

Matching Material to Application

The most important thing to think about when choosing a fire blanket is how you’ll use it. Fiberglass blankets are good for home use because they're affordable and work well. They can handle small kitchen fires or protect furniture from fireplace embers. For tougher jobs, like welding or in factories with high heat, a silica-based fire blanket is better. They cost more, but they can handle much higher temperatures. If you need something resistant to chemicals or really tough, special materials like Nomex or Kevlar might be what you need.

Balancing Budget and Protection

Your budget matters. More expensive materials offer more protection, but you might not need them. Fiberglass blankets offer good protection for common household problems at a fair price. For higher-risk situations, though, spending more on silica or other advanced materials is a good idea. Putting safety first is important. Think about what a fire could cost you versus the price of a good fire blanket.

Simplifying Maintenance Requirements

Different fire blanket materials require different levels of care. Fiberglass blankets are usually easy to care for. You just need to check them for damage sometimes. Some special materials might need more care or professional cleaning. This is important to consider, especially for businesses. Easier maintenance means lower costs over time and makes sure the blanket will work when you need it most.

To make choosing easier, here’s a table showing which materials work best for different situations.

Fire Blanket Material Selection Guide

To help you choose the right fire blanket, the table below compares different materials based on their best uses, cost, and safety features.

| Application | Recommended Material | Temperature Range | Price Range | Key Benefits |

|---|---|---|---|---|

| Home Kitchen | Fiberglass | Up to 550°C | Low | Affordable, easy to use, readily available |

| Industrial Welding | Silica | Up to 1800°C | High | Superior heat resistance, durability |

| Chemical Laboratory | Nomex/Kevlar | Varies | High | Chemical resistance, high strength |

| Automotive (General) | Fiberglass | Up to 550°C | Medium | Affordable, lightweight, easy to store |

| Automotive (EV Battery) | Silica/Specialized | Varies | High | High heat resistance, specialized protection |

This table summarizes the most important factors for each use. It helps you choose a fire blanket that offers the best protection for what you need. Think about your situation and put safety first when making your final decision.

Safety Standards And Material Certification Requirements

Not all fire blankets offer the same level of protection. Understanding safety standards and material certifications is essential to ensure your fire blanket provides genuine safety and not a false sense of security. Knowing which certifications are important could be the difference between quickly extinguishing a small fire and facing a much more dangerous situation.

International Safety Standards for Fire Blankets

Several international standards define the performance requirements of fire blankets. These standards establish criteria such as heat resistance, durability, and flame spread. For instance, the European Standard EN 1869:1997 outlines specific requirements for fire blankets intended for kitchen use. Other standards address industrial and commercial applications, creating consistent quality benchmarks across different markets. This helps ensure a minimum level of performance no matter where the fire blanket is purchased.

Testing and Certification Processes

Fire blankets undergo rigorous testing to ensure they comply with safety standards. Flame spread tests determine how quickly fire spreads across the blanket’s surface. Thermal protection evaluations assess the blanket's ability to prevent heat transfer, which is critical for protecting the user from burns. Accredited laboratories conduct these tests to provide objective data that validates the effectiveness of a fire blanket.

Certifications: Separating Marketing Hype From Genuine Quality

The fire safety market has numerous certifications. However, not all certifications are equal. Some are genuine indicators of quality, backed by rigorous testing and adherence to established standards, while others are primarily marketing tactics with little substance. This is why it's essential to research and verify certifications before purchasing a fire blanket. Look for certifications from reputable organizations such as UL (Underwriters Laboratories) or BSI (British Standards Institution). These certifications demonstrate that a product has met stringent safety requirements. For additional safety information, see our guide on Do fire blankets expire?.

Verifying Authenticity and Avoiding Substandard Products

Counterfeit certifications and substandard fire blankets present a significant risk. These products might not perform as expected during a fire, potentially endangering lives and property. To mitigate these risks, verify certifications directly with the certifying organization. Check for verifiable markings, serial numbers, or other signs of authenticity. Be wary of extremely low prices, which might suggest a low-quality product. Investing in a quality fire blanket from a trusted supplier is an investment in your safety.

Evolving Standards and Ongoing Research

Safety standards are constantly evolving. Ongoing research and development continuously improve fire safety technology. New materials and manufacturing techniques lead to more effective and durable fire blankets. Staying informed about these evolving standards and choosing products certified to the latest specifications is important for ensuring you have the best protection available. As technology progresses, choosing a fire blanket will involve not only understanding current certifications but also keeping an eye on future innovations in fire safety.

Protect your home and loved ones with our high-quality fire blankets. Visit fireblanket.com today to browse our selection of fire safety products and invest in peace of mind.